Impact Studies

Revolutionizing Pipeline Rehabilitation with Autonomous Robotics

Industry

Market Leadership

Global Reach

The Challenge

Azuria Water Solutions faced several critical challenges in maintaining and upgrading aging water and sewer pipes:

The Solution

BrightAI developed an AI-powered platform for Azuria, automating pipeline inspection and rehabilitation to improve crew productivity, enhance precision, and reduce costly rework.

What our partners are saying:

BrightAI’s Augmented Cut technology ensures precise lateral reinstatements without damaging the host pipe or liner. This game-changing reliability helps us get the job done right every time.

Jim O’Brien, Senior Equipment Manager, Azuria

Real-time intelligence

Automates complex tasks like identifying pipe geometry and PACP codes, reducing the skill requirements and enabling efficient, precise relocation.

From reactive to proactive

AI-powered automation supports human reviewers by increasing accuracy in defect recognition and maintaining continuous oversight, helping to speed up the process.

Real-time pattern detection, issue prediction, and problem diagnosis with PACP-certified* accuracy.

*PACP = Pipeline Assessment Certification Program. This is a standardized system designed for consistent coding of sewer pipe inspection footage.

Automating operations

A cloud-based portal where clients can review project data, access reports, and approve work remotely, streamlining processes.

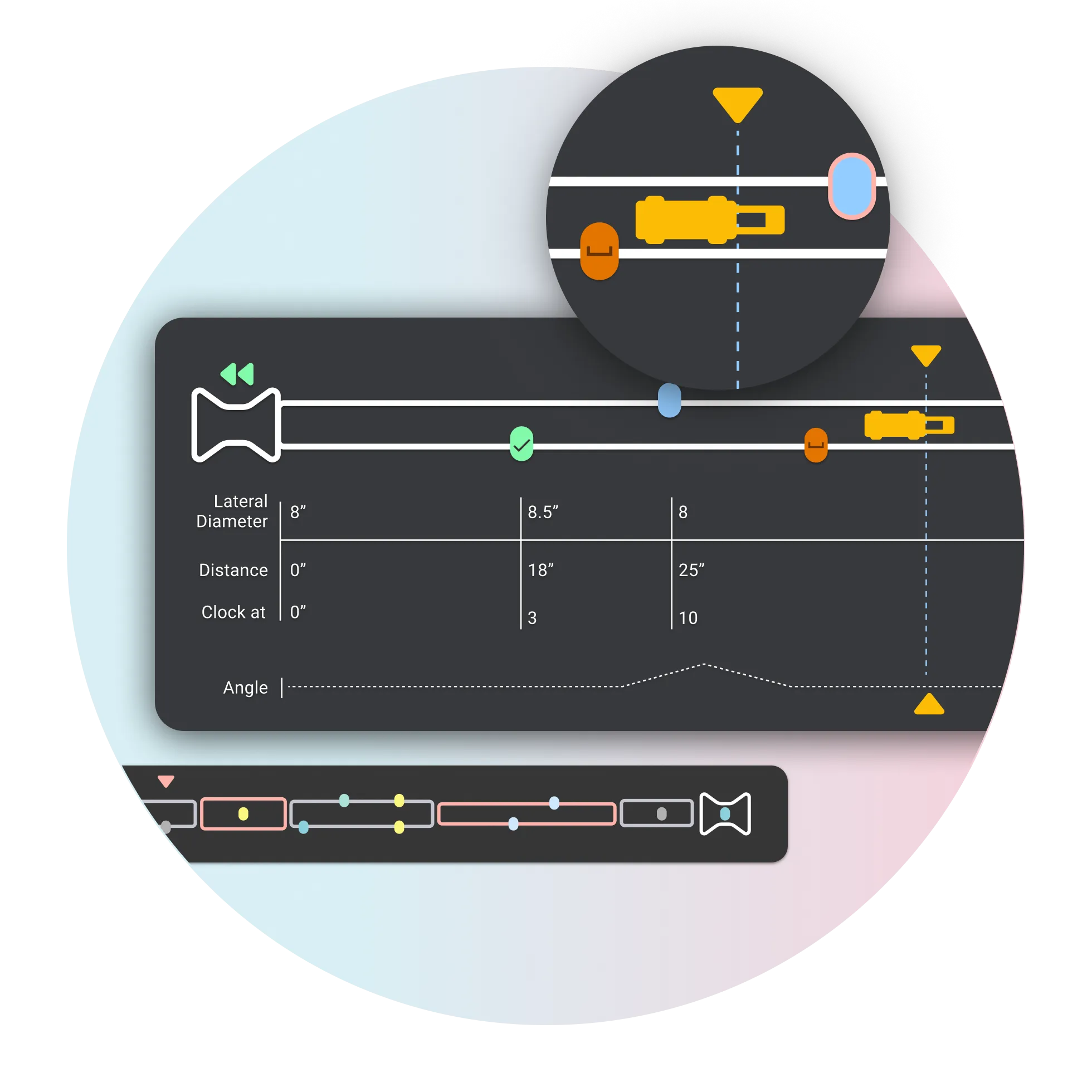

Enhances visibility and data collection while guiding the robot down the pipe for pre-inspection and relining.

Field engineers can monitor the robot's activity in real-time. Cleaning crews can swiftly identify and address red flags before liner installation.

Infrared and camera technology assists operators in precisely locating and cutting laterals after relining pipes and ensuring accuracy.

Truck App

Video feed with AI automatically identifying a lateral connection.

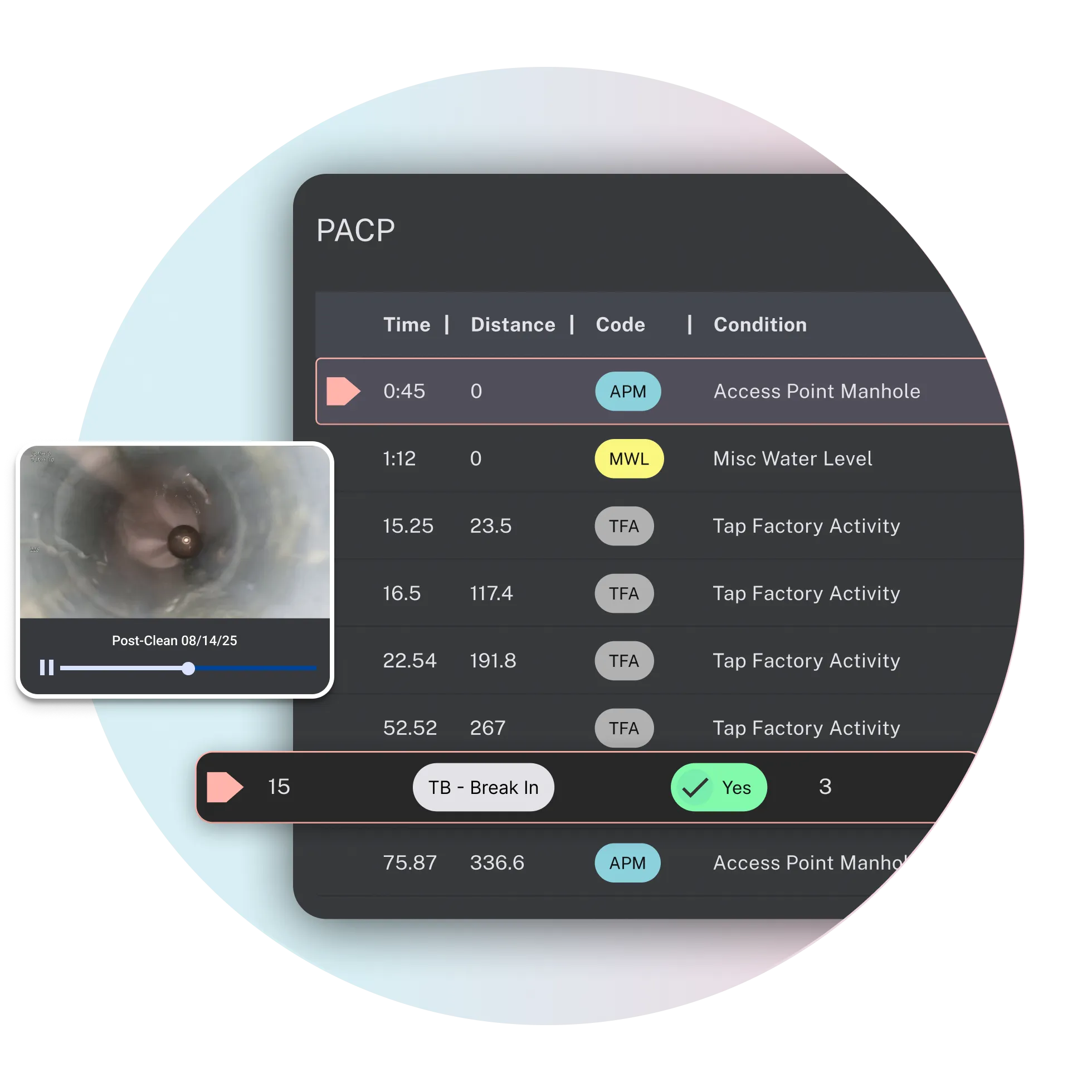

Portal

Displaying the digital twin of the scanned pipeline alongside PACP code listings from the inspection. Highlighted red codes signal issues requiring attention from the project manager or field engineer before lining can proceed.

Digital Twin

A real-time graphical representation of the pipe, creating new segments whenever the pipe diameter changes. PACP codes appear as colored dots, allowing users to click and instantly view specific points. This feature saves time by identifying issues before repairs begin.

What our partners are saying:

BrightAI has got a unique combination of both the dreamy side of it - and then the ability to actually engineer it and bring it to life.

Rob Tullman, CEO, Azuria

Benefits:

Operational Efficiency

Quality Improvements

Market Growth

Scaling for the future

BrightAI’s partnership with Azuria Water Solutions is setting a new standard in water and sewer infrastructure rehabilitation—efficient, accurate, and AI-driven. This collaboration reinforces BrightAI’s leadership in AI for critical infrastructure. BrightAI’s hands-on support, including full-time tech support in the field, demonstrates the company’s unwavering commitment to ensuring the success of its customers. By closely collaborating with Azuria, BrightAI continues to refine and enhance its solutions, ensuring they deliver measurable value in the field and supporting Azuria’s expansion.