Intelligence in motion

BrightAI for Water Pipeline

AI-Powered Inspection and Rehabilitation for Water Pipelines

BrightAI’s Augmented Cut technology ensures precise lateral reinstatements without damaging the host pipe or liner. This game-changing reliability helps us get the job done right every time.

Jim O’Brien, Senior Equipment Manager, Azuria

Challenge

Aging water infrastructure poses persistent challenges, including manual assessments, errors, and costly rework that delay timely rehabilitation. BrightAI partnered with Azuria Water Solutions to address these issues by enabling precision, speed, and proactive capabilities in pipeline inspection and rehabilitation.

Solution

The Stateful Operating System (OS) enables a proactive approach to pipeline maintenance, transforming operations from reactive problem-solving to streamlined autonomy.

Business Impact

Acceleration

Accelerates project timelines by reducing manual intervention.

Precision

Improves precision in inspections, cutting, and repairs.

Cost Reduction

Minimizes costly rework and ensures faster job completion.

Productivity

Increases productivity with crews and technicians increasing their capacity to inspect more miles of pipeline.

What We Enable

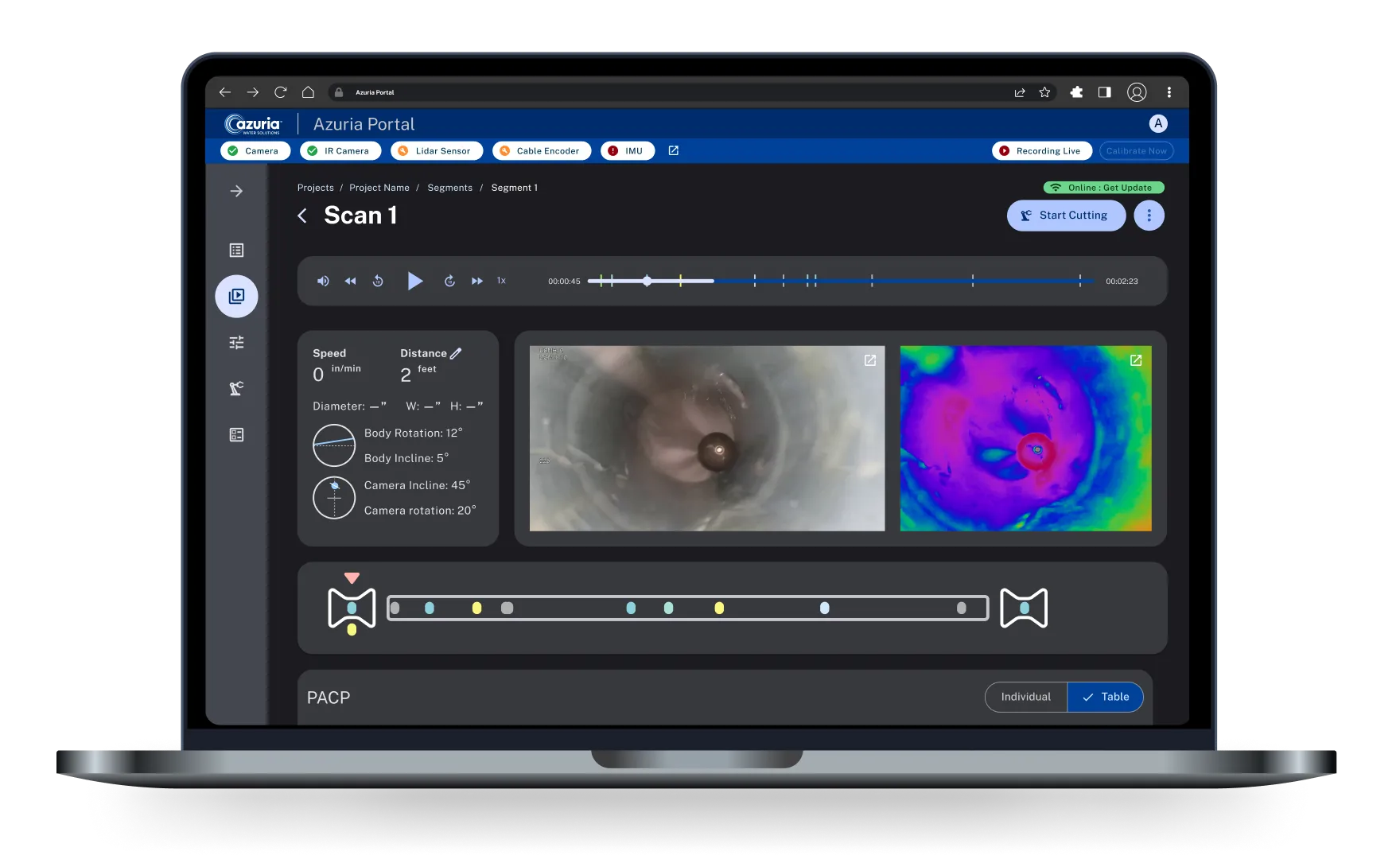

Monitor: The robot conducts a pre-scan, creating a digital twin with PACP codes and pipe geometry. This real-time data unlocks a deep understanding of pipeline conditions.

Diagnose: Stateful OS analyzes the pipeline’s readiness for relining and flags detailed measurements, precise lateral locations, and any potential issues.

Act: With accurate data, operators confidently assess the conditions, reline, make precise cuts within the pipe system while completing jobs faster.

What We Deliver

Stateful AI Hub: Automates complex tasks like identifying pipe geometry and PACP codes, reducing the skill requirements and enabling efficient, precise relocation.

Autonomous Inspection Portal: A cloud-based portal where clients can review project data, access reports, and approve work remotely, streamlining processes.

Stateful Multimodal Robot Head Unit: Enhances visibility and data collection while guiding the robot down the pipe for pre-inspection and relining.

Truck App: Field engineers can monitor the robot's activity in real-time. Cleaning crews can swiftly identify and address red flags before liner installation.

Augmented Cut: Infrared and camera technology assists operators in precisely locating and cutting laterals after relining pipes and ensuring accuracy.

The Future

BrightAI is set to transform pipeline rehabilitation with fully autonomous features in the future. This evolution will empower Azuria to harness AI-driven autonomy, delivering faster, more cost-effective, and reliable pipeline management worldwide.

Read the full Impact Study