Impact Studies

Automating Pest Control for Food and Pharma Safety

Industry

Market Leadership

Global Reach

The Challenge

The pest control industry faces several challenges, and Pelsis identified opportunities to enhance methods with AI-powered automation.

The Solution

BrightAI partnered with Pelsis to create an AI-powered platform that automates pest monitoring, boosts operational efficiency, and ensures compliance in food and pharmaceutical facilities. The digital ILTs (insect light traps) use ultraviolet light to attract insects, which land on a glue board visible to a camera inside. The camera captures an image, and the AI hub inside the trap analyzes and classifies the overall count, size, and species. This data is then sent to the cloud, providing real-time insights.

What our partners are saying:

Up to 40% of the pest control workforce are expected to retire in the next 10 years, creating a major challenge. Pelsis Digital helps attract younger, tech-savvy professionals by offering advanced insights, smarter workflows, and a more modern approach to service differentiation.

Claire Larcombe, Global Portfolio Director, Pelsis

Real-time intelligence

Automates pest activity monitoring in ILTs, providing real-time insights and freeing technicians to focus on critical areas.

From reactive to proactive

Learns continuously to quickly detect pest patterns, predict issues, and offer diagnostic solutions.

Connects field technicians with HQ to address pest issues before they escalate. Real time understanding of insect count, trends, and potential threats.

Automating operations

A centralized platform for tracking pest trends, generating reports, and ensuring compliance across multiple sites.

Guides field technicians to specific glue boards and areas requiring intervention, optimizing response times.

High-resolution cameras and AI automate insect counting making species identification possible, reducing manual inspections and pesticide use.

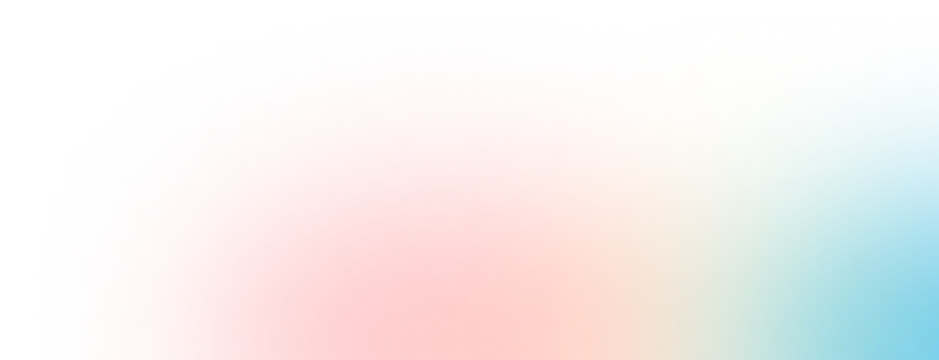

Web Portal

Management can monitor all devices at each location through a centralized dashboard.

Real-Time Reporting

Remotely access glue boards to verify issues and confirm ground truth.

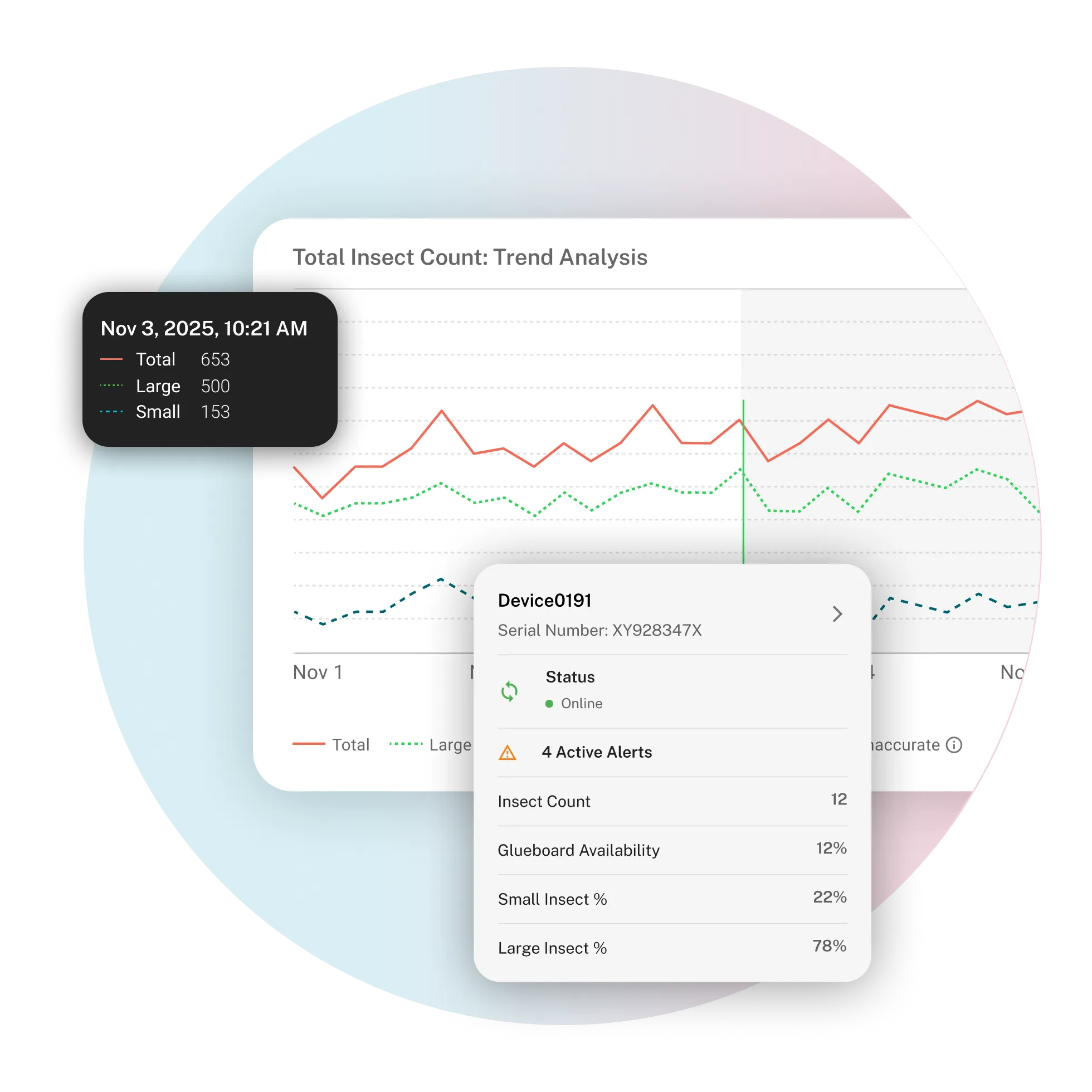

The App

The app provides remote access to each ILT, with customizable alerts for insect counts and glue board capacity. Users can set alert intervals—every 15 minutes, hourly, 12 hours, daily, and more. When thresholds are reached, technicians are notified to replace glue boards as needed and then update the app to reset counts and confirm status.

What our partners are saying:

Monitoring with over 90% accuracy gives pest control operators the certainty needed to take action when necessary.

Nuno Lourenco, Head of Product Engineering, Pelsis

Benefits:

Operational Efficiency

Sustainability & Safety

Scaling for the future

Since its launch, Pelsis has expanded the AI insect light trap product across multiple lines and into new markets globally. The product is already being piloted with top food and pharma giants, setting a new standard for pest management.